T-Roof YEP 2500

Fastening occurs at the overlap mechanically in the lower sheet alternatively open and visible through both sheets with roofing felt nails dim 25x2.5 mm. Overlap occurs with adhesive edge against adhesive edge and for any cross joint or similar with approved roofing felt adhesive. Consider the weather conditions when installing adhesive edges. Warm the rolls in a warm storage if the temperature is below +10°C.

Important!

Unless otherwise stated here, the latest recommendations in AMA Hus (JSB.6) apply.

- The permanent surface layer determines the minimum roof slope for the underlay felt, but always at least 1.5° (1:40) when exposed but not battened. When battening and exposing without the outer roof covering, at least 14° (1:4)! If battening is needed at a slope below 14° (1:4), it should be done directly in conjunction with the installation of the outer roof.

- For open and visible fastening, consider roof slopes <14° (<1:4) as the underlay may be exposed to precipitation and/or if the outer roofing is not installed immediately. Coat the nailing with Sealant K-36 or equivalent repair compound for bitumen waterproofing.

- When covering with flat roof tiles, the supplier's guidelines for the underlay paper must be followed!

- For concealed fastening, carefully check the strength of the joint after installation. Consider adverse weather conditions and ensure any temporary securing of overlaps or protective covering until the permanent surface layer is installed!

- The adhesive edge has aggressive adhesion under normal conditions! In cooler weather (<+10°C), there may sometimes be a need to improve the adhesion.

- Use a heat gun and gently warm the adhesive surfaces. Press the seam together carefully! In cool weather, rolls should be pre-stored for at least 1 day in a warm storage

- Be mindful to gently load the surface and immediately repair any damage with roofing felt adhesive Sealant K-36 or equivalent repair compound for bitumen waterproofing. For larger damage, use and attach/glue a strip from the underlay felt.

- Mechanical fastening with concealed attachment hot-dip galvanized roofing felt nail min 25x2.5 mm.

- Always cover with the surface layer (tiles, metal sheets, etc.) as soon as possible to avoid exposure to sunlight and adverse weather conditions. During construction, the underlay can be exposed to sunlight for up to a maximum of 4 months. In the usage stage, the underlay should be protected by the outer roof covering.

- Rolls should be stored upright on a flat, dry surface and protected from sun and precipitation.

- T-Roof YEP 2500 is diffusion-tight and when mounted on a wooden substrate, the space underneath should be ventilated according to standard practice.

1. Installation

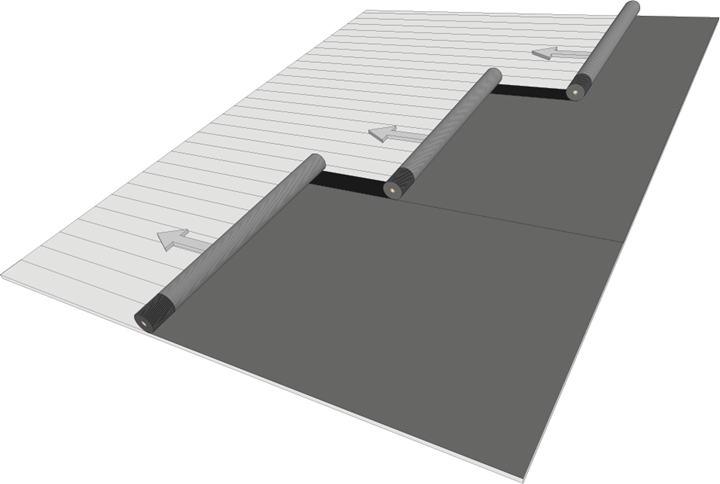

Installation is done with strips across the direction of the roof slope. Rolling is done from right to left so that the side

the top side is rolled out inward. The sheets are easiest laid from the bottom and with overlapping subsequent upwards. The substrate should be dry, even, and stable to avoid deflection and movement. The surface layer determines the substrate's condition and minimum slope. For the minimum underlying panel thickness, see table AMA HSD. 1331/1 (AMA-Hus 21). For battened roofs, at least 20 mm tongue and groove, and for non-battened, at least 23 mm. NOTE! The space under the wooden substrate or above the insulation should be ventilated according to practice.

2. Gables

Starting and ending against gables is best done with a triangular strip that angles the base upwards.

The underlay fabric is folded around the strip and fastened visibly on the outside.

3. Joints

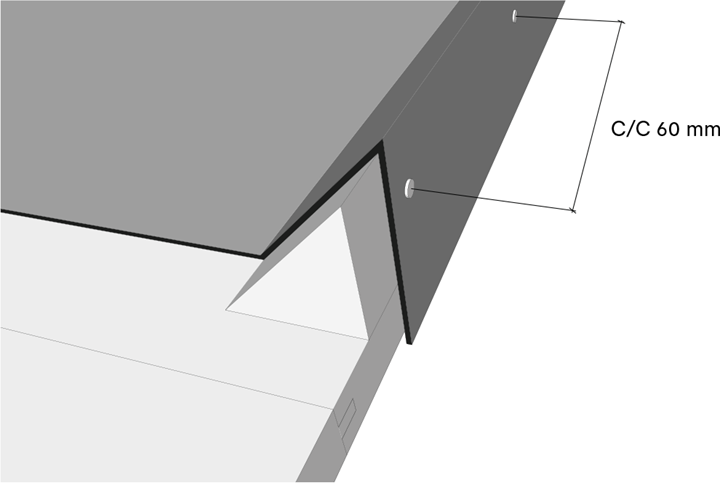

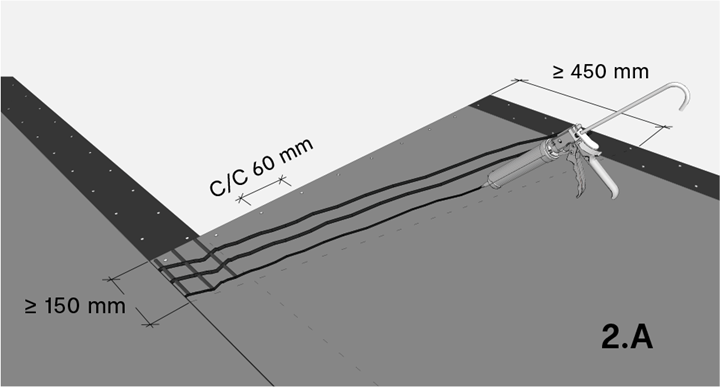

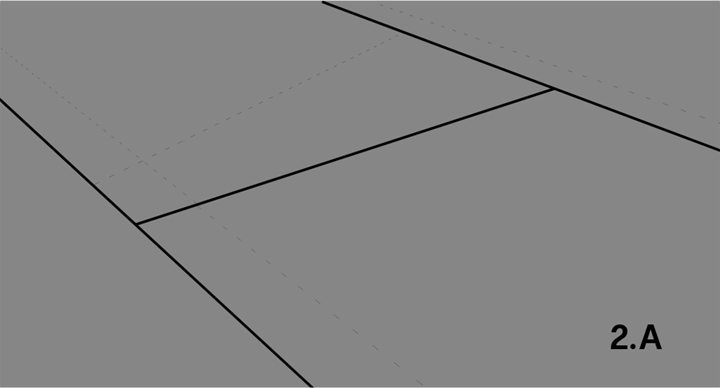

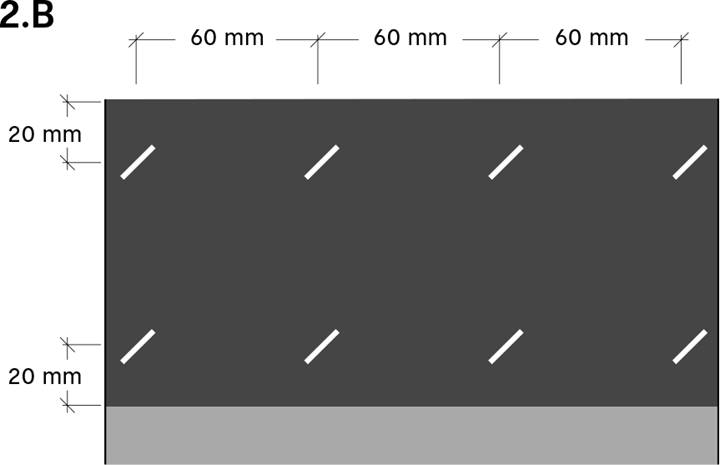

The underlay paper is mechanically fastened with roofing felt nails min 25 x 2.5 mm (see fig 2.B). Mechanical fastening is done at the longitudinal edges hidden in the upper adhesive edge of the sheet. Open and visible fastening (through both sheets in the overlap) can alternatively be done with only roofing felt nails and at slopes from 14° (approx. 1:4) and upwards (for flat banded sheet metal, hidden fastening is required). The sheet is temporarily fastened at the top edge (approx. 1 m between fastenings) and adjusted at the bottom edge. Overlapped in a straight edge line, the protective films are then removed simultaneously with careful pressure afterwards. Overlap occurs with adhesive edge against adhesive edge corresponding to the recommended overlap. NOTE! In the case of hidden mechanical fastening, carefully check the strength of the joint afterwards. Consider more difficult weather conditions and ensure any temporary fixing of the overlaps or protective covering until the permanent surface layer is installed! Alternatively, battening if possible! At transverse joints, the overlapping sheet at the lower edge should overlap at least 150 mm and then be cut diagonally upwards so that the overlap at the top becomes like the lower (150 mm) + 300 mm. The lower sheet is fastened at the edge with mechanical fastening c- dimension 60 mm (see fig 2.A). Transverse joints should be glued down with 3 strands of roofing felt adhesive corresponding to Sealant K-36.

4. Eaves

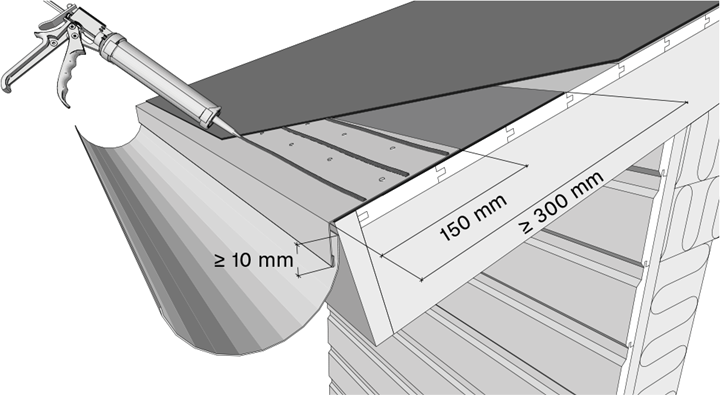

At the eaves, the first strip is attached at the lower edge against the recommended eaves flashing with the adhesive edge

(Do not forget to remove the protective film!) and 3 sticks of roofing felt adhesive equivalent to Sealant K-36 (see fig 3). The finish is done a bit up (about 20 mm) so that it is concealed by the protective surface layer in the usage environment. Adhesion should be done on cleaned metal. The eaves plate should be mounted on a strip of underlay above the wooden substrate (e.g., T-Roof Multi Strip).

5. Ridge ventilated

A ventilated ridge is arranged with an end at the wooden substrate's end towards the ventilated opening. Fasten at the top with roofing felt nails. Ensure that the ridge board is covered with an adapted strip of the underlay fabric down towards and out onto the top of the counter battens so that it is clamped by the topmost load-bearing batten.

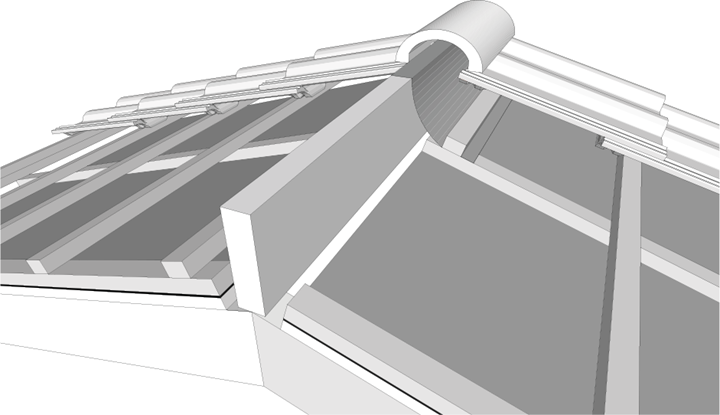

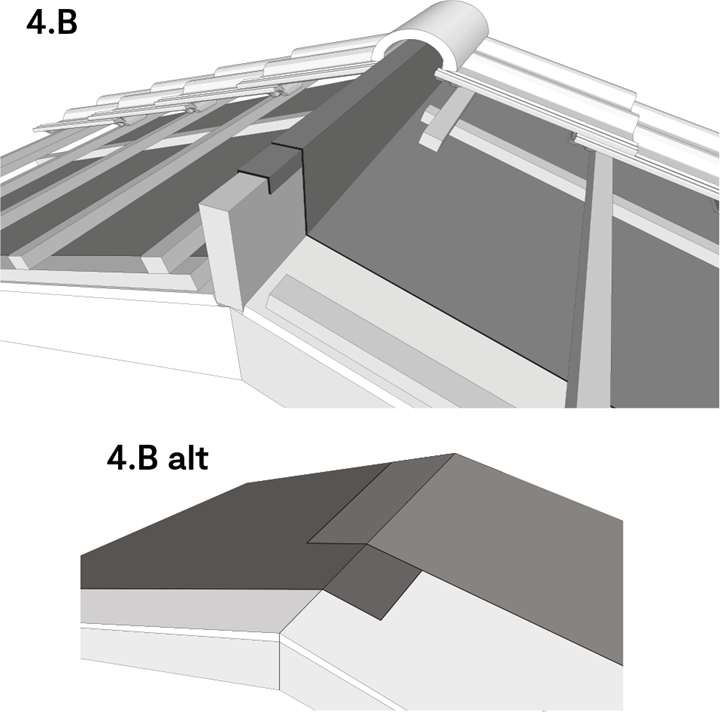

6. Ridge sealed

At a tight ridge, make a pull towards the top edge of the ridge board and over to the other side, fasten mechanically with

for example, roofing felt nails. The covering of the ridge board is done from both sides of the roof and also constitutes the overlap of the underlay felt. If no ridge board is used, the overlap should occur from each side of the roof and total at least 500 mm. The lower sheet is fastened with, for example, roofing felt nails, and the upper is glued down with roofing felt adhesive equivalent to Sealant K-36. Alternative according to image 4.B alt, occurs without a ridge board

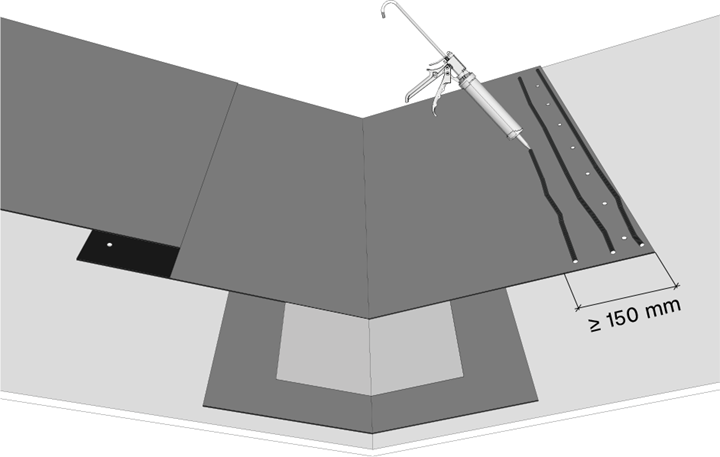

7. Valley

First ensure that the valley gutter has a stable and fixed base with a metal underlay (minimum 300 mm wide). The underlay should be provided with a strip of underlay felt underneath. The underlay should be nailed to mechanically hold the roof sides together. In a valley gutter with valley metal, the gutter should be provided with a strip of underlay felt (according to fig 5). The strip in the valley gutter is fastened at the ridge and at the outer edges with, for example, roofing felt nails c-measure 100 mm. Then let the adjoining strips from each roof side overlap the valley strip by at least 150 mm. The fastening is done with roofing felt adhesive equivalent to Sealant K-36.

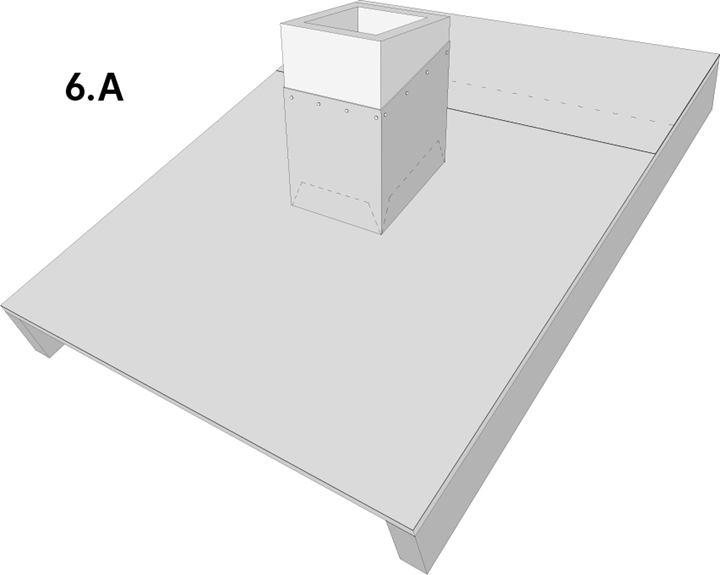

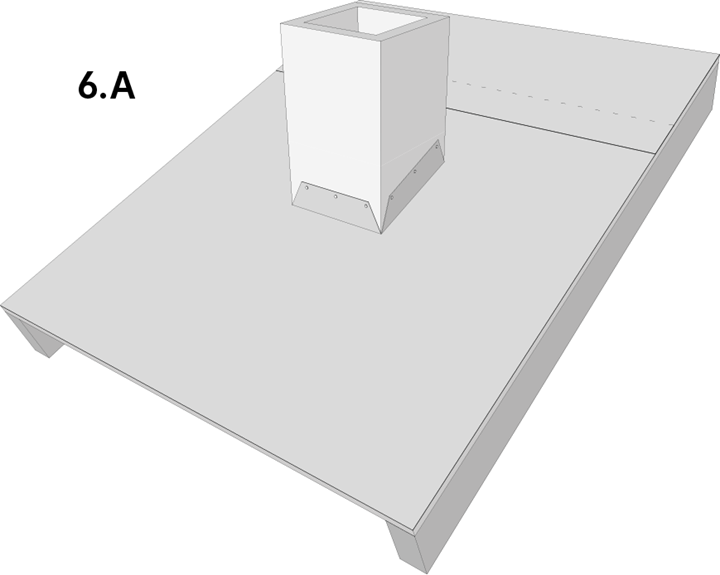

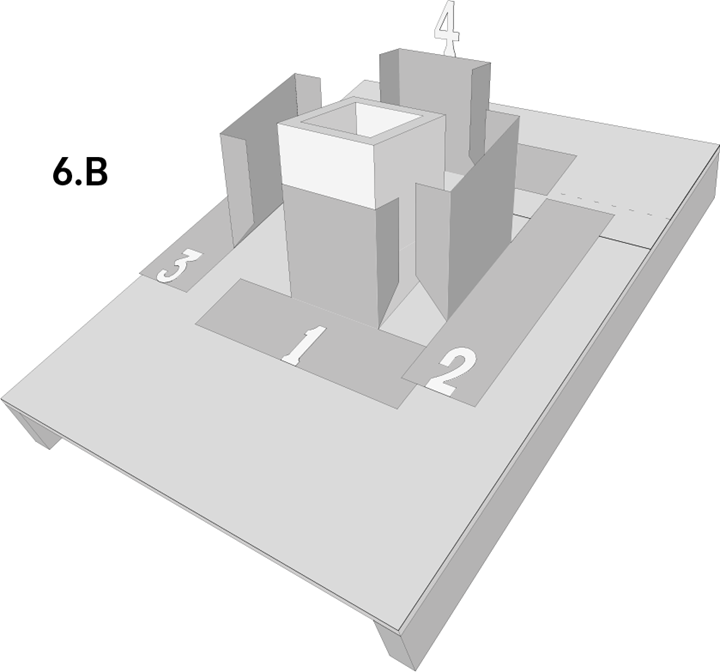

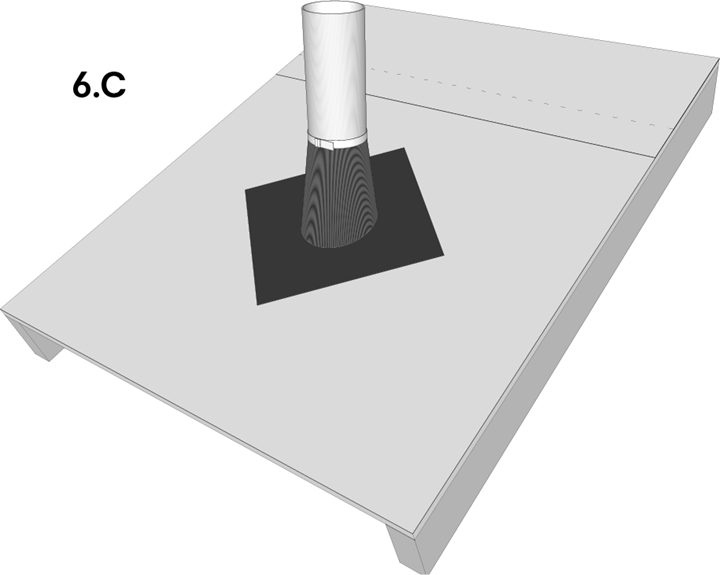

8. Implementation options A, B, and C

A. For square penetrations (chimney, ventilation duct, etc.), the underlay paper should be cut, folded up, and nailed at the bottom (see fig 6.A). Then cover the fold with a strip of underlay paper all around with an overlap (at least 300 mm high). Fasten with nails and glue (80 mm wide or 3 strands) or nail at the bottom. Nailing is done with a c-measure of at least 100 mm. Gluing is done with Sealant K-36 or equivalent. The corners are sealed extra with Sealant K-36 or equivalent sealant or with elastic durable sealing tape. Penetrations in battened constructions are finally provided with an underflashing of metal at the bottom and all around!

B. For square penetrations and lower roof slopes (≤12°/1:5), higher safety and installation with glued collars are recommended (according to fig 6.B). Cut out four sides from the underlay paper (overlap 150 mm), trim and attach the bottom one first with the following two sides, and finish with the rear one towards the ridge. Gluing is done on all edges with Sealant K-36 or equivalent (80 mm wide or with 3 beads).

C. For round penetrations such as holes for ventilation pipes, etc., a flange like self-adhesive T-Flange butyl or full rubber flange is used (see fig 6.C). The base of the flange is fully adhered to the substrate and the underlay paper. For full rubber flanges, adhesion should be done with Sealant K-36 or equivalent. For a square base, one of the flange's corners should be positioned straight up towards the ridge during adhesion. The flange should be sealed at the top with a clamping ring or at least 2 turns of durable sealing tape.

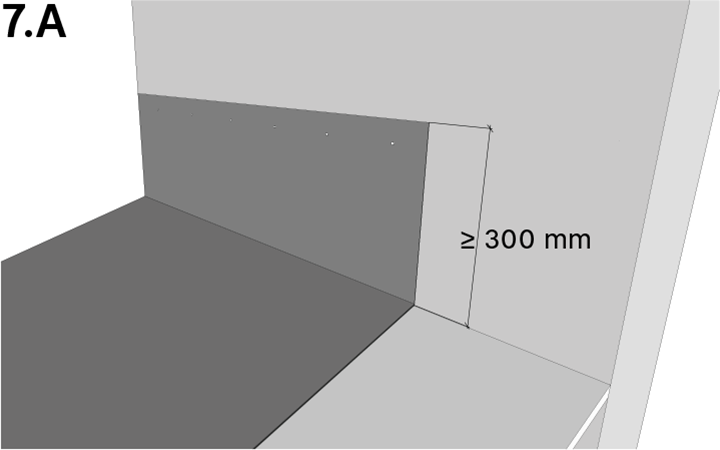

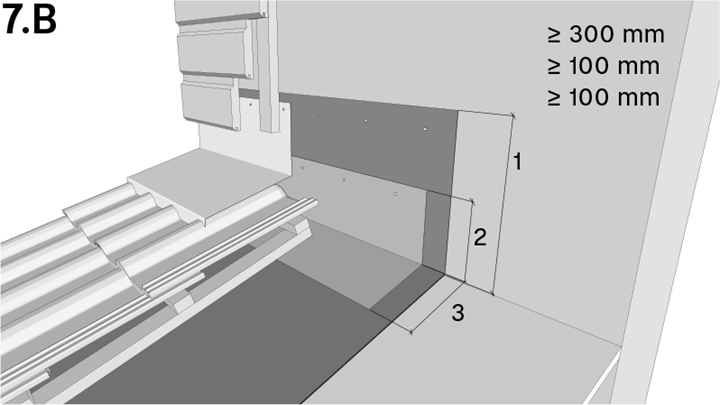

9. Vertical connection (wall)

At the connection where the roof underlay at the top edge meets the wall (according to fig 7.A), an extension on the adjoining wall should be made, at least 300 mm. The extension is made under the facade and attached to the windproof layer with roofing felt nails at 100 mm centers and 30 mm from the edge. For battened outer roofs, the connection is provided with a metal flashing above the underlay (according to fig 7.B).