Important!

- Details such as overlap joints, fastenings, pipe and cable penetrations, or for example beams, should be sealed airtight with approved aids for the inner climate shield system, such as tape (T-Flex), grommets, sealant, or double-sided tape. See system description!

- Mechanical fastening (staples/nails) of the vapor barrier must always be galvanized. Fastening with staples should be taped (with T-Flex) for optimal airtightness.

- Consider the attachment of the climate screen. The vapor barrier should be fixed with a minimum center distance of 600 mm on a solid frame structure. Additional fastening is required for folds or extensions.

- Connections/seals of the vapor barrier between different types of construction materials, where the vapor barrier is fixed, such as between wood and concrete or steel/sheet metal, should be made with an extra length of the vapor barrier in folds/waves just before the connection (approximately 50 mm).

- Creases in the foil that meet the taped joint across should be sealed extra with at least 200 mm of taping over the taped overlap and along the crease (100 mm in each direction). This extra taping should follow the bottom and top of the crease!

- An internal climate screen should always be mounted offset into the outer wall (maximum 1/3 of the total insulation thickness). The shown installation should/can be equipped with an insulated zone inside the vapor barrier (serves as an installation zone for electricity, etc.).

- The variable vapor barrier (T-Vap Pro) should not be used in constructions where spaces with permanently high humidity are allowed (e.g., swimming pools). However, this does not apply to kitchens or equivalent bathrooms in residences.

- During installation and in colder seasons, consider the risk of condensation on the inside of the external wind barrier. With the insulation in place, this risk increases significantly, which is why a quick installation of the internal climate screen (vapor barrier) counteracts the risk of condensation.

- The use of the Vapor Barrier in roof constructions is possible if the requirement for fall-through safety has been considered. This applies to roof constructions such as sloped roofs. However, not in roofs against cold attics, which may require additional moisture investigation and fall-through protection. The product should not be used on concrete surfaces as the alkali resistance has not been evaluated.

- The vapor barrier is stored and kept packaged/protected from sunlight (UV radiation) or constantly higher temperatures (>+35°C).

- The vapor barrier is freely exposed (not built-in) with UV protection that corresponds to the construction time (< 3 months).

Wall

Installation of load-bearing interior walls should occur after the vapor barrier has been installed on the exterior wall, or alternatively, a strip of the vapor barrier should be installed between the load-bearing interior wall and the exterior wall. Taping of all joints is done with Sealing Tape T-Flex for complete tightness and durability. Fastening and joining to concrete is done with Joint Tape T-Duo Concrete.

1. Roll out the vapor barrier and cut to the desired length. Always allow for at least 200 mm overlap.

2. Attach the vapor barrier to the top edge/hammer beam of the wall. The overlap occurs from the ceiling down onto the wall's vapor barrier. The joint should be clamped between a stud and another stud or sheet material.

3. Secure the vapor barrier firmly to the wall (with galvanized staples or battens with a minimum c-distance of 600 mm or double-sided joint tape T-Duo). The vapor barrier should be finished so that it covers the inside of the wall's sill and is folded out onto the floor above the floor's vapor barrier with at least 200 mm for overlapping the floor's foil. Alternatively, the vapor barrier is finished without overlap with tape against the sill (T-Flex) or with T-Duo Concrete down to any concrete slab.

4. The vertical joint should be executed clamped over the standing stud with an overlap of at least 200 mm. The overlap is taped (T-Flex).

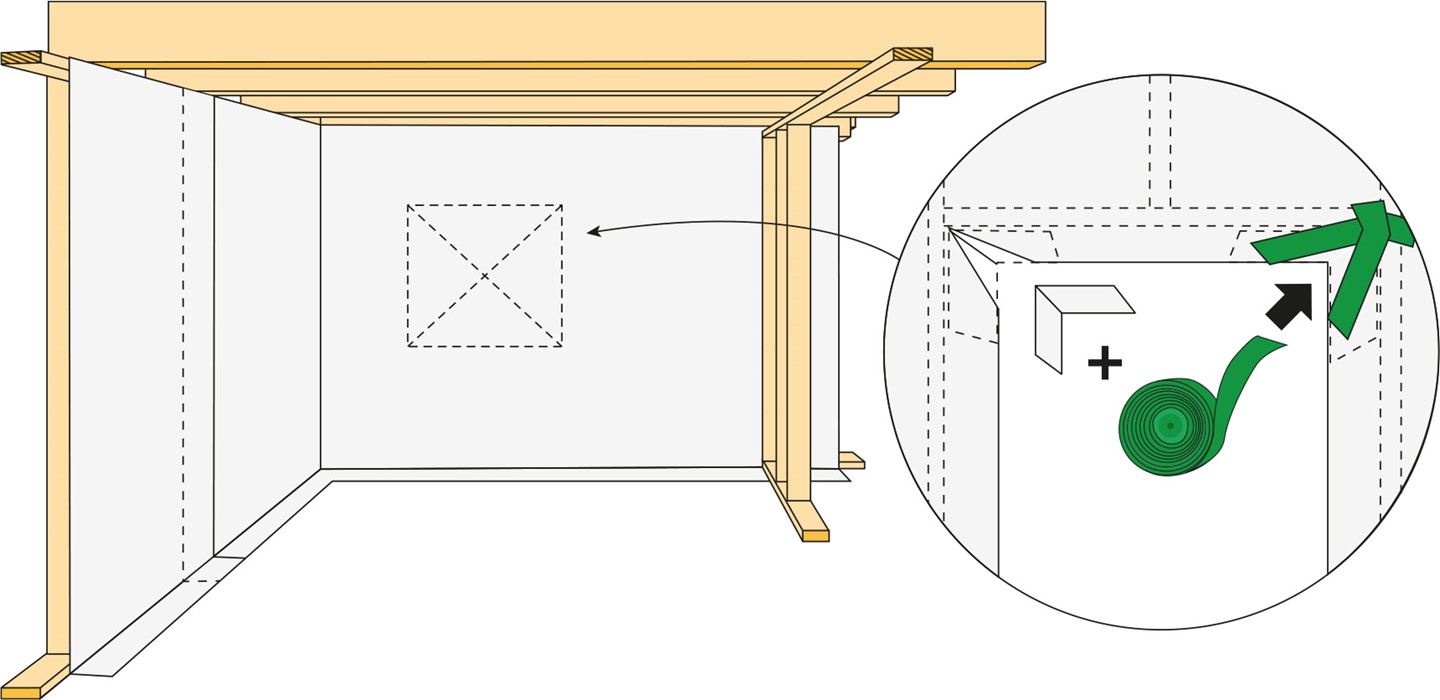

5. Be extra careful with the attachment points around window and door openings. In frame openings, the easiest way is to make a cross-cut (Alternative cutting can be done and the taping should then be equally airtight) of the vapor barrier, from corner to corner. The vapor barrier is then folded out into the frame's recess and fastened with staples or tape. Before fastening, extra pieces of vapor barrier (square) with folding should be placed under the flaps in each corner so that they are completely covered with the vapor barrier! Edges and joints are taped (T-Flex). The piece of vapor barrier can be replaced with tape or sheets of tape (T-Flex).

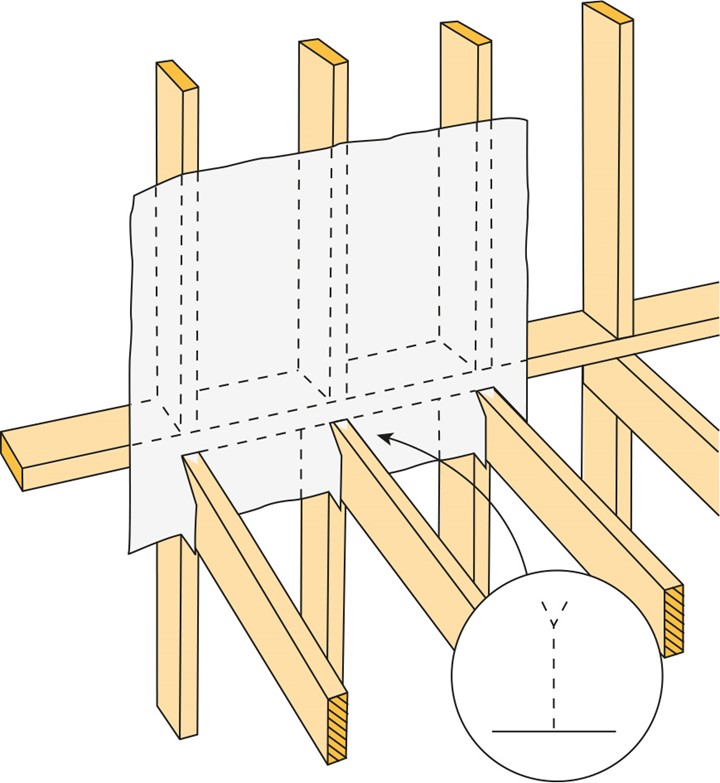

Floor Joists

1. Cut or use an appropriate size of the vapor barrier (length and width) with respect to the center distance of the beams. The rolling should be done from top to bottom. Adjust the size of the vapor barrier so that it ends at the bottom edge of the floor structure. From below, the vapor barrier of the underlying floor should be pulled up and overlap equally.

2. Attach with staples and start at an upright stud/support leg. Allow a flap of at least 100 mm to extend on each side of the outermost studs (support legs).

3. The vapor barrier is unfolded on the beams in the joist and Y-cuts are made to fold it down in between. Secure and staple each flap around the beams.

4. Seal/tape around each beam carefully with Sealing Tape T-Flex. All overlaps and joints are done with taping (T-Flex).