Important!

- The floor sealing should be completely integrated and protected within the construction after assembly and during the building period.

- The function of airtightness is highly dependent on the Floor Seal being installed under tension and clamped according to the details in the installation instructions.

- The assembly should be carried out with connecting details in the construction that are not exposed to movements during the operational stage!

Assembly

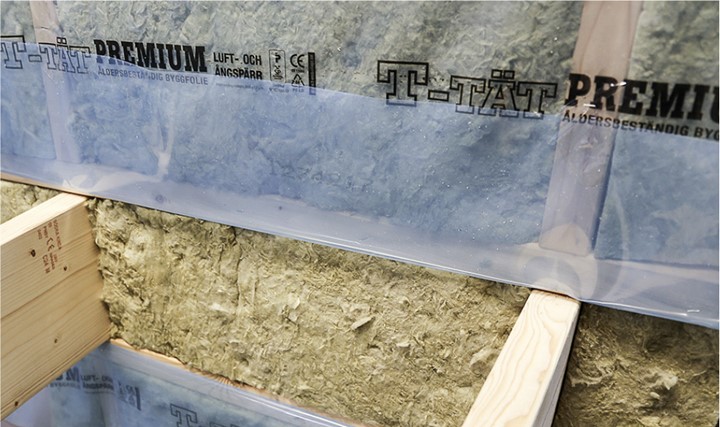

The floor sealing is intended for airtight and moisture-protective solutions in exterior wall constructions at floor connections. Its main intended function is as a seal between the internal climate screen (vapor barrier, vapor brake) meeting from below and above, as well as connecting beams from the floor structure.

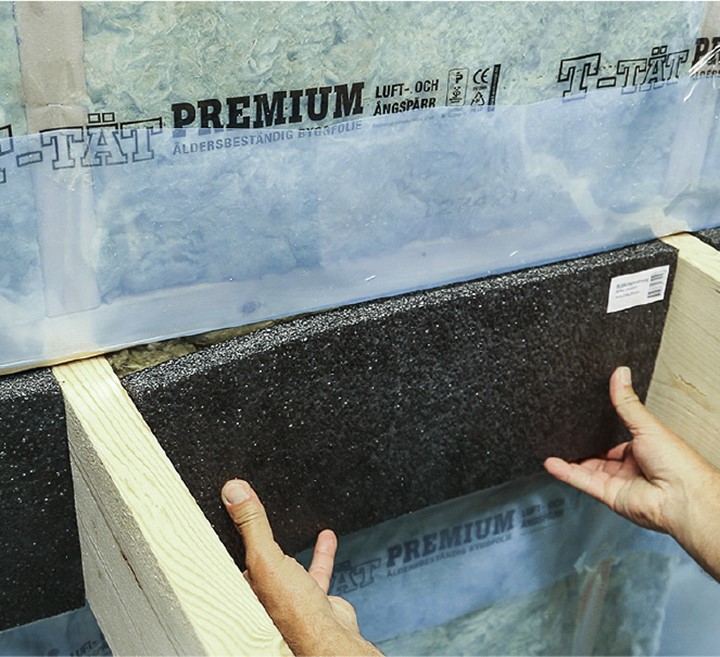

The floor sealing is placed one piece between a pair of beams in the same position and layer as the adjoining inner climate screen from above and below. The board should be slightly bent and clamped in with its designed excess dimension. The connection to and from the climate screen is partly done with butyl compound T Fix and with fixing and pressing from wooden battens/beams around. For further details, see the separate installation instructions!

1.

Fold up the upper climate screen (e.g., vapor barrier) so that the insulation at the junction of the floor structure and the outer wall is clearly visible.

2.

Install the floorboard with bending and pressure so that it is clamped between the wooden beams and at the same level. The board should be mounted directly against the insulation in the wall connection, and only the thickness of the board should protrude inward from the level/line of the insulation and climate screen. In case of deviating center measurements, which are less than 600 mm, the board can be adjusted and cut to the smaller measurement with an additional measurement of +5 mm. So that the installation always occurs with a clamped and tight connection all around!

3.

Apply a string of T-Fix butyl compound approximately 10 mm thick on the top side of the board and the top of the beams. The string must be completely unbroken all the way where the climate screen is to be connected to ensure airtightness!

4.

Fold down the climate screen towards the adhesive strip, press it down gently against the board and the top of the beams. Smooth out and secure the climate screen with staples.

5.

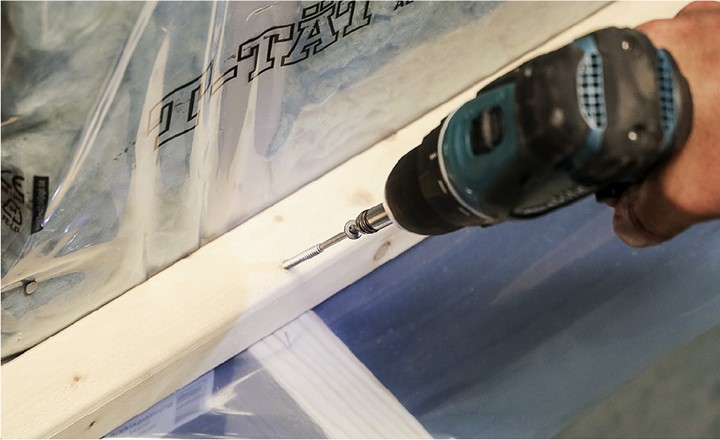

Mount and screw a bottom rail (min 28x 70 or 45x 45 mm) or alternatively a floor chipboard as a fixture against and over the newly glued connection in the corner. The rail forms a stable support against the surface and joint for optimal tightness.

6.

Repeat the same assembly of items 3, 4, and 5 but on the underside of the floorboard!

7.

The assembly is complete!