FormPlate

FormPlate replaces plastic channel casting boards when casting foundations with reinforcement cages.

Important!

- Mechanical fastening is done with assembly screws (min 40 mm), farmer screws (min 40 mm) or alternatively screws and washers (TECCA art.no 296015).

- The product should be stored indoors or outdoors protected from precipitation.

- When the disc is correctly mounted in the reinforcement cage (folded down at the top), it can remain outside for up to two weeks before being used for casting.

- The mold must be backfilled before casting.

- The casting board made from bio-based material decomposes and decays when left in the ground after casting.

- The disc should never be folded more than double.

- Always start the assembly at a corner.

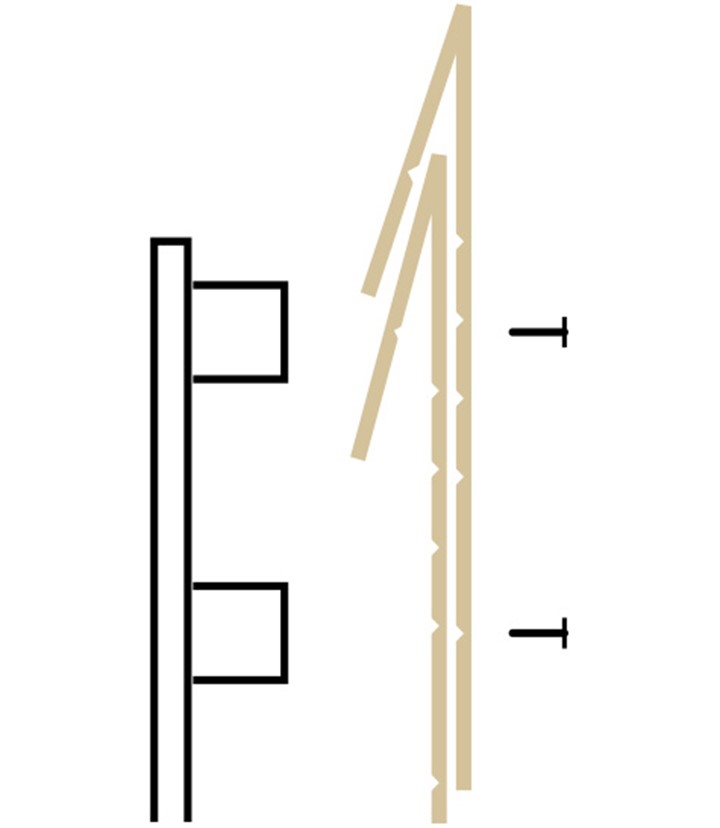

1. Preparation

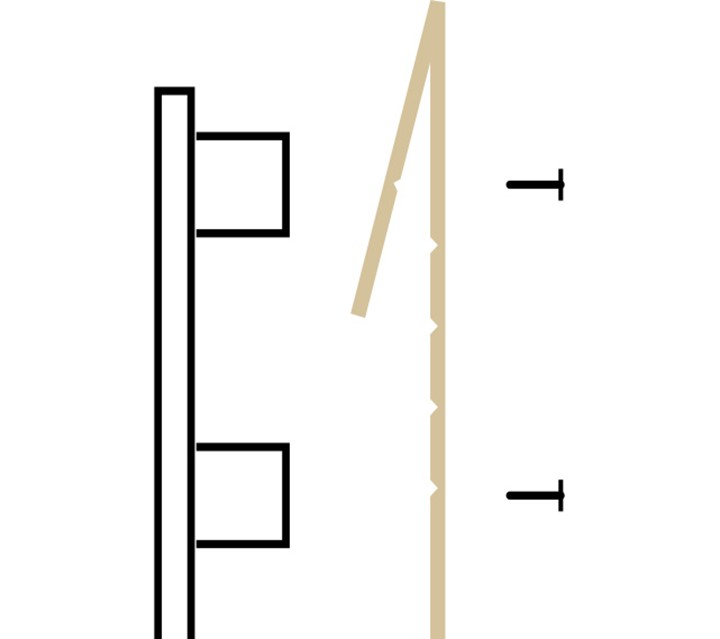

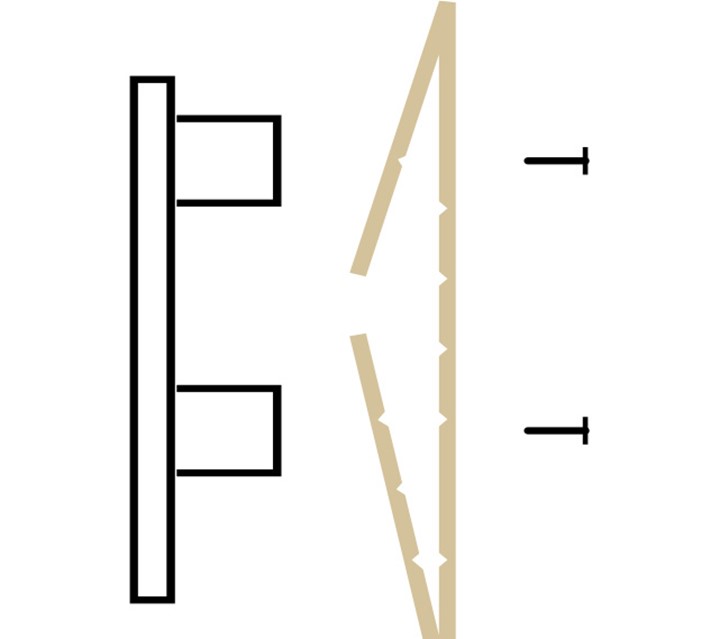

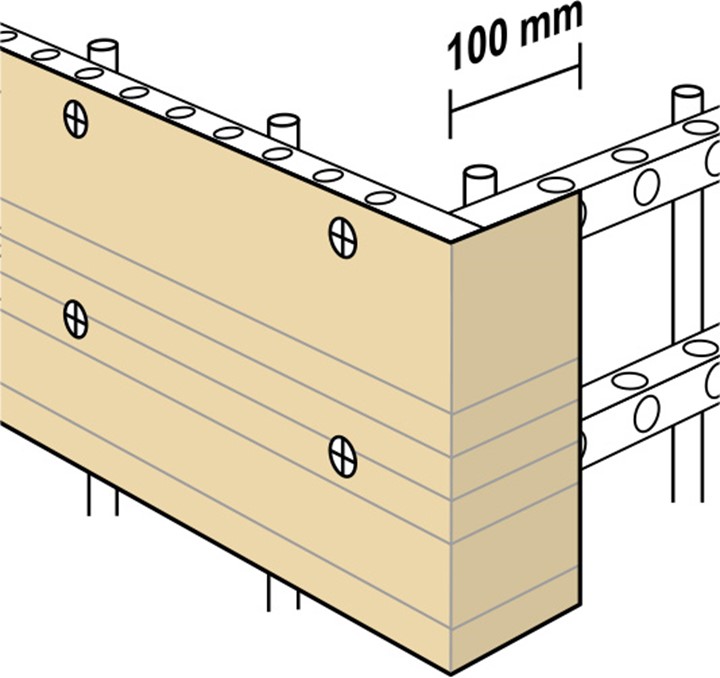

The casting board should always be folded double at the top edge so that the screw attached to the top spacer strip always goes through two layers of corrugated cardboard. The minimum recommended fold down is the top fold line on the board (100 mm).

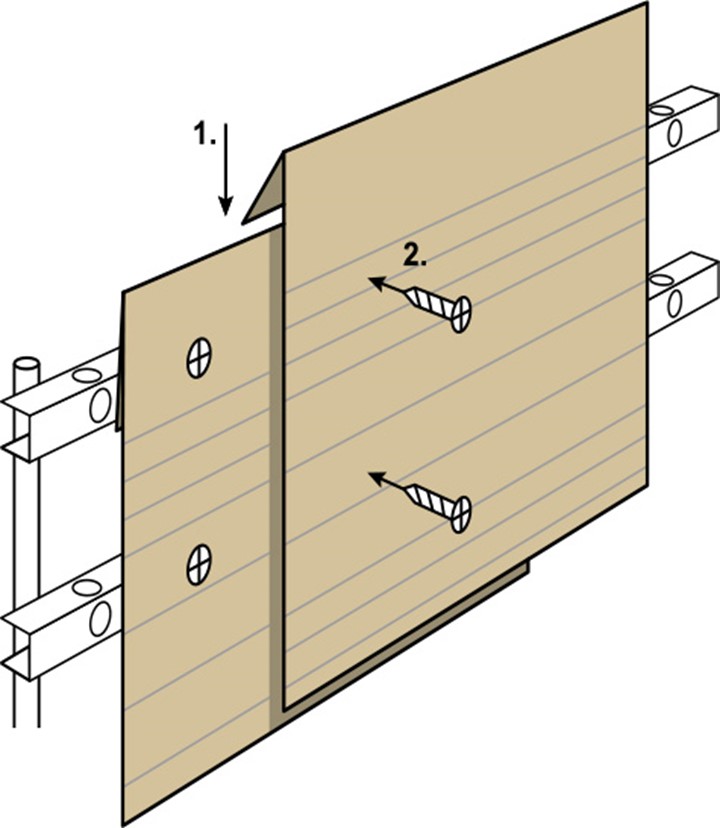

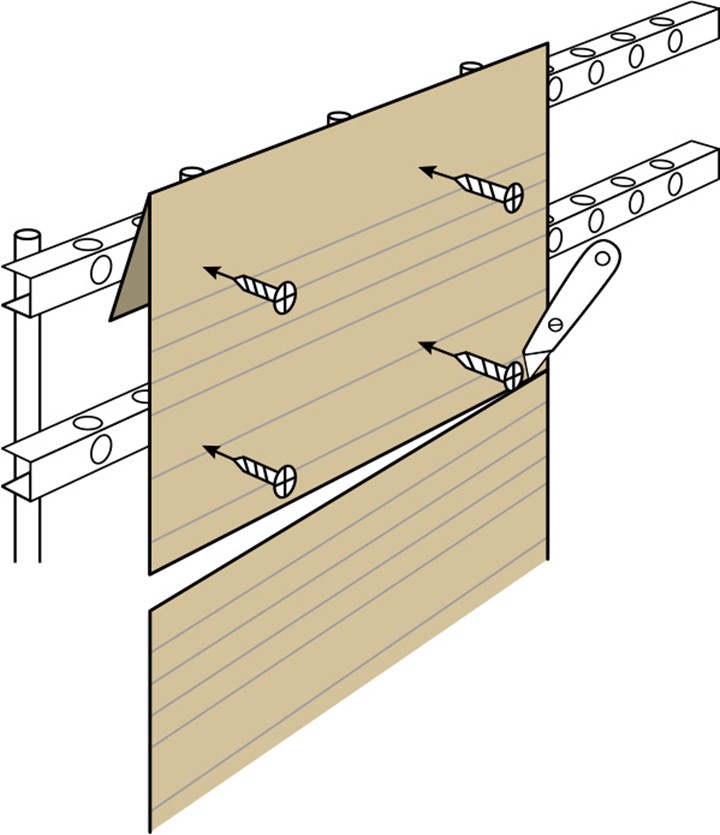

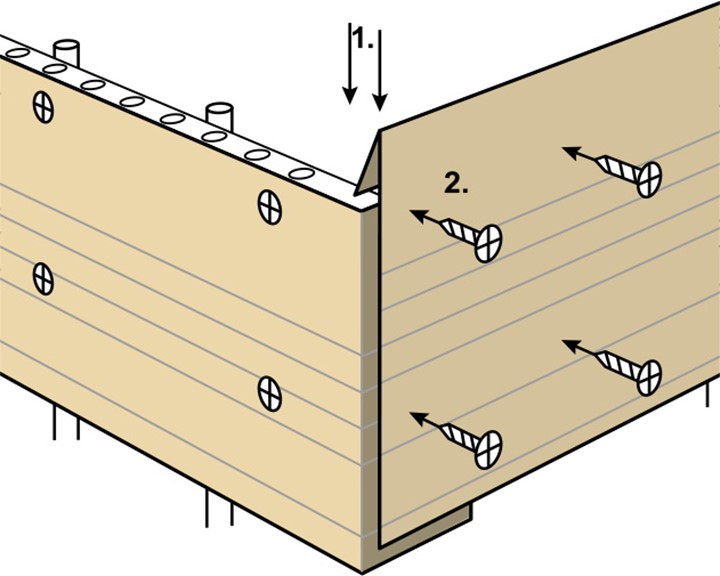

2. Fastening

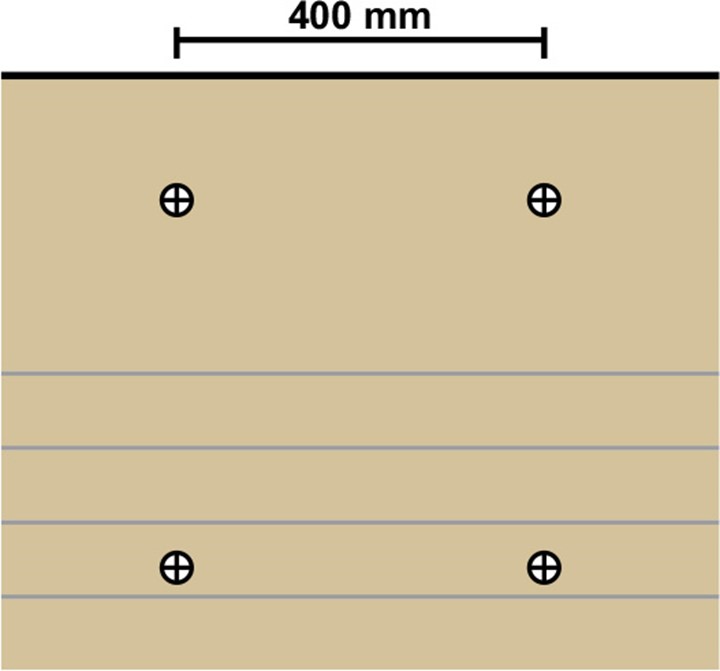

The recommended fastening is mounting screw (min 40 mm), farmer screw (min 40 mm) or alternatively screw and washer (TECCA art.no 296015). The board is mounted with a maximum of 400 mm between the fastening points. The screw should be attached to the spacer strip, through the corrugated cardboard. Place the screw as close to the center of the spacer strip as possible (without hitting the holes in the spacer strip) and fasten into each spacer strip.

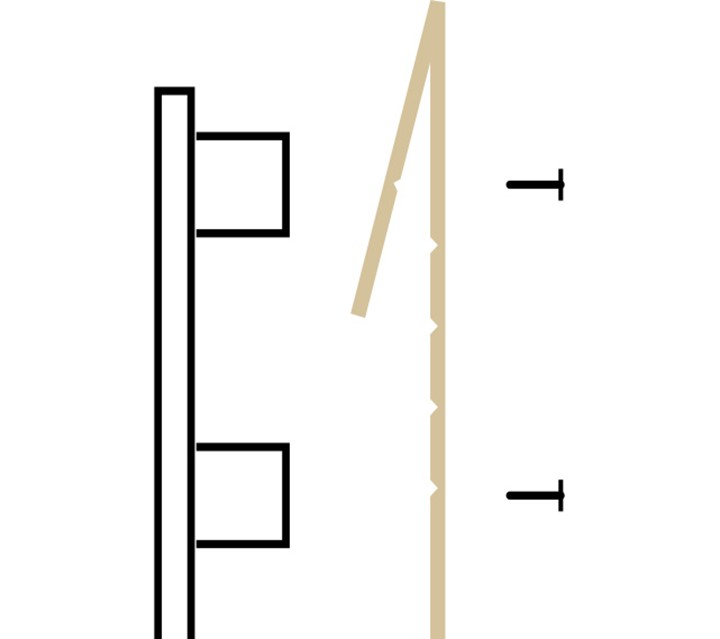

3.A Adjust the disc's height

Cut off the remaining material at the bottom to possibly reuse it. Alternatively, make a larger fold at the top.

3.B Adjust the disc's height

If you don't want any waste, fold the casting board double at the bottom. The casting board should never be folded more than double.

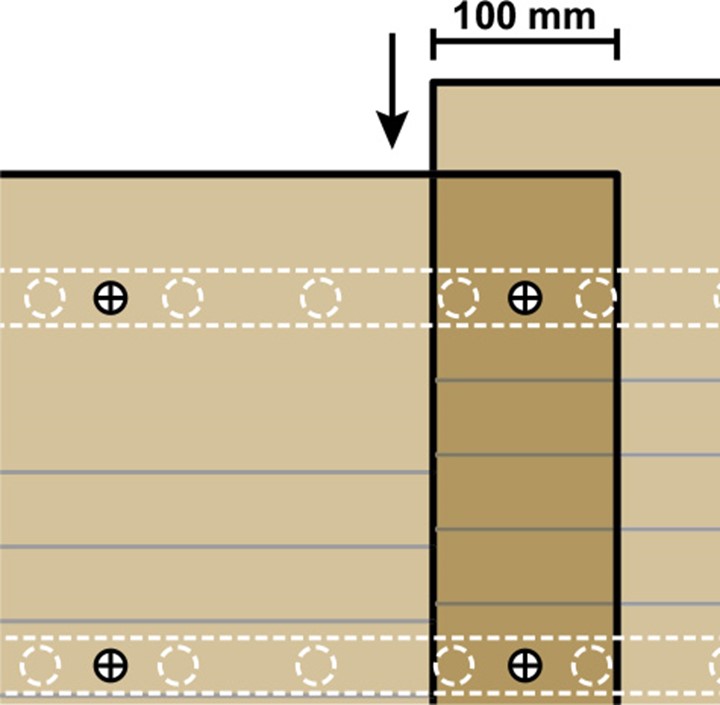

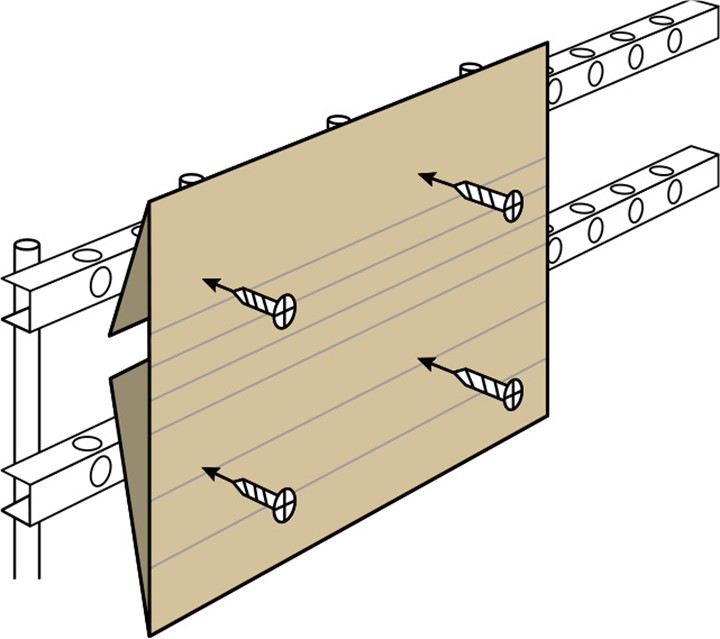

4. Start Assembly

Always start by mounting the first panel by folding around a corner. Leave at least 100 mm around the corner to be able to join with the next panel. Slide the upper panel around the lower one as shown in the picture.

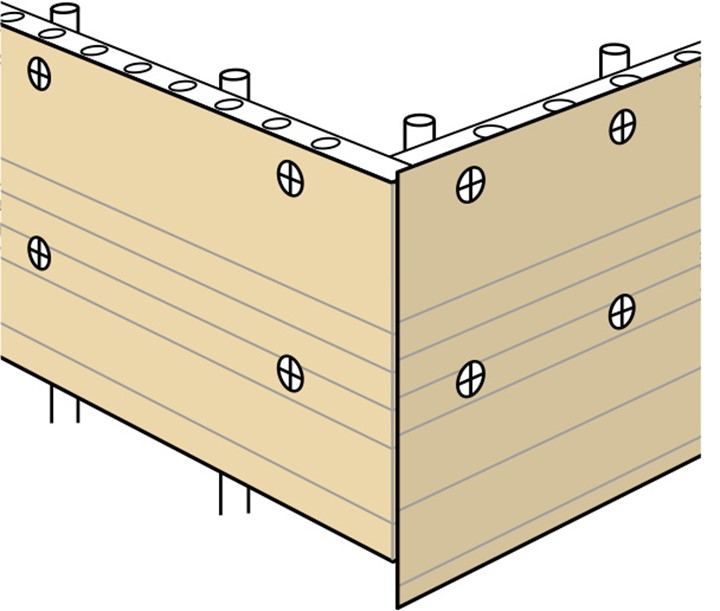

5. Joining

When splicing, the upper casting board is folded over the lower mounted casting board. The joint should always be at least 100 mm and is fastened with screws in the spacer strip. Slide the upper board around the lower one as shown in the picture