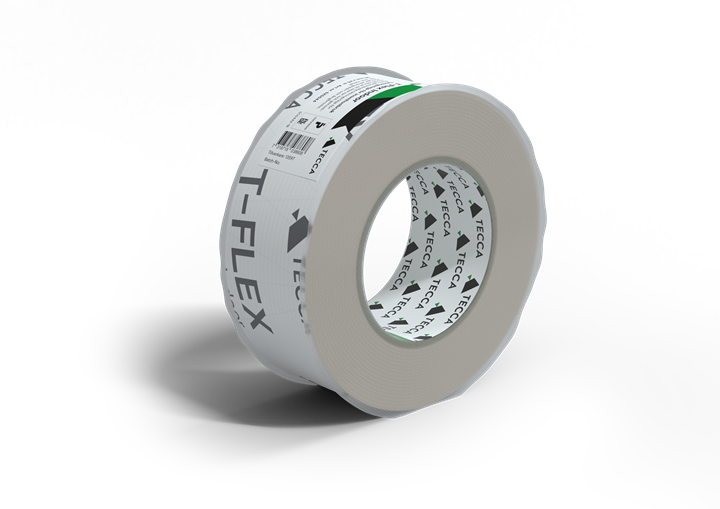

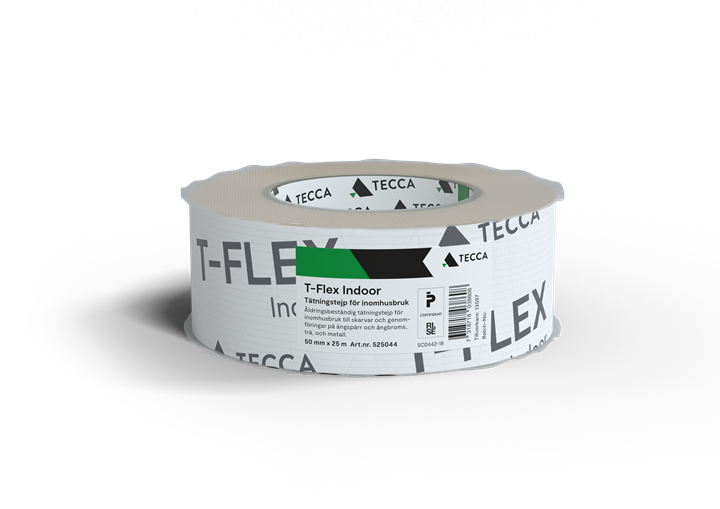

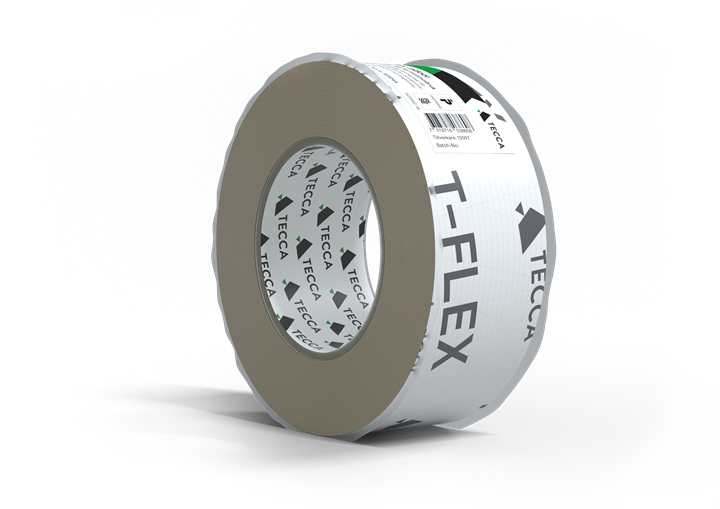

T-Flex Indoor

T-Flex Indoor is a diffusion-tight construction tape for indoor use. The tape has optimized properties that provide high adhesion and long durability, and it is also P-marked. The tape is made of a co-polyethylene, reinforced with polyester threads, and coated with an aggressive acrylic adhesive. A silicone-coated release paper serves as adhesive protection. The materials used are free from toxins and solvents.

Optimal for indoor use

Age-resistant for at least 50 years

Application Area

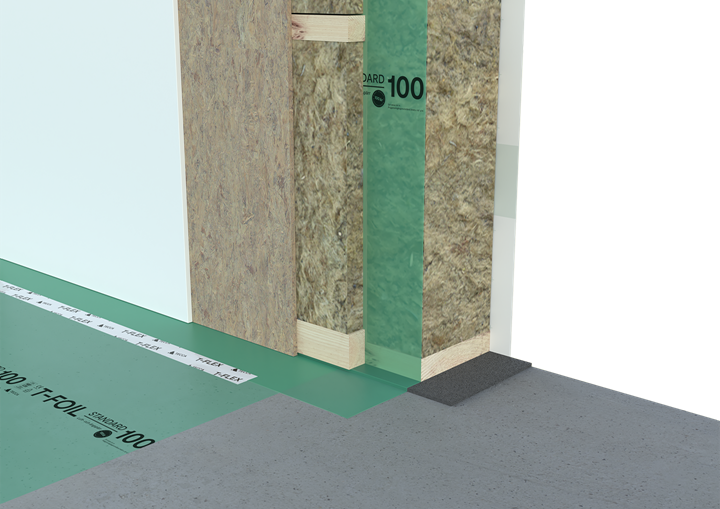

T-Flex Indoor is used as moisture and air sealing tape indoors. For example, for joints, pass-throughs, or damage to vapor barriers (PE film), vapor retarders (Non Woven), PVC, wood (planed or lacquered), glass, and metal, etc.

Harmful moisture and vapor are prevented by the tape from being transported out or into sensitive building parts (prevents convection and diffusion). In a system installed for the inner part of the climate screen, the tape counteracts energy losses (heat leakage) in insulated constructions.

The product has a 30-year warranty.

Installation

The tape is always applied to the surface with firm and strong thumb or finger pressure. Post-processing is preferably done with a roller or plastic spatula. See the applicable installation instructions.

Approval

T-Flex Indoor has a P-marking and testing for aging resistance (SPCR 031) is performed by RISE (Research Institutes of Sweden).

Important!

- Note that movements in the substrate should be minimized for optimal durability and test the adhesion on the substrate before installation.

- The surface should be clean (consider surface treatments), grease-free (silicone-free), dry, and smooth. Follow the recommended working temperature for best results.

- Do not stretch the tape too elastically as it will always try to return to its original shape and width.

- Consider forces and movements in the underlying foil (or membrane). Especially free-hanging and non-fixed substrates where temperature fluctuations (e.g., temporary higher temperatures during construction) can create tensions and movements in the tape joint due to the influence of self-weight!

- Ensure that the base is properly secured and fixed according to the accompanying installation instructions or reinforce the taping (support tape, wider tape) corresponding to the additional load that may occur!

- When assembling in lower temperatures, the tape should be stored in a warm storage before assembly for the best assembly results.

- When taping at lower temperatures: The tape will achieve its final strength when the temperature is above

+5°C. The assembly and application against the substrate should be compensated with higher pressure! - In general, tape applications should be free from tensile stress. This should be particularly considered at low

processing temperatures. - To ensure age resistance, the tape should be stored or installed in the operating environment protected from sunlight (UV radiation) and not exposed to temperatures above +35°C.

- For identification, always tape up the first piece with the label visible!

Articles

- Name Art.nr Specification

Technical specification

- Material: Polyethylene film with polyester mesh reinforcement and modified acrylic adhesive. Silicone paper, which is removed during installation.

- Length: 25 m

- Width: 50 mm

- Thickness: 0.28 mm

- Color: White with gray print

- Temperature range: -40°C to +110°C

- Recommended working temperature: +5 °C to + 25 °C

- Lowest possible working temperature: 0 C°

- Waterproofness: Tight/high

- Vapor tightness: Diffusion tight

- Aging resistance: At least 50 years

Accessories for T-Flex Indoor

Do you need help or have questions about our products?

Try our chatbot

Our chatbot Tea is based on AI and has been trained on all the information available on the website. You can find Tea at the bottom right corner.

Search among questions and answers

We often receive many interesting questions, and we have compiled the most common ones in one place.

Contact our staff

If you need to talk to us, we are of course also available by phone or email!