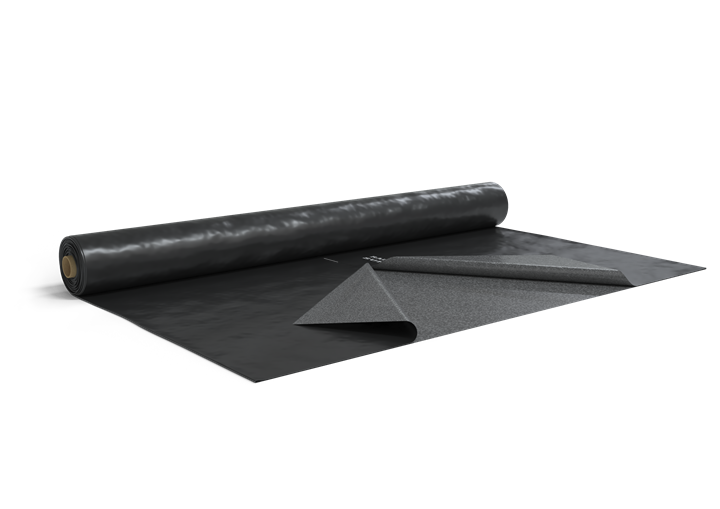

Radon membrane Super

The radon membrane consists of a specially manufactured robust multi-layer film of polyethylene (LD-) with a friction coating on the top side. The membrane is aging resistant. The sealing system includes the radon membrane with associated joint aids such as tapes, bands, and sleeves (see accessories).

At least 50 years of aging resistance

High wear resistance

Multiple mounting options

Application Area

Radon Membrane Super is used as a radon-protective sealing system on and in foundation structures and for burial in the ground. The system prevents radon gas from rising from below and spreading into the building. The membrane is diffusion-tight and exhibits properties similar to a moisture barrier. Moisture protection against the substrate (e.g., concrete slab) is thus achieved with the system.

Installation

Radon membrane Super is installed completely with the friction coating facing upwards with overlap for joints and always completely sealed (air, radon, moisture). This applies to any perforations or fastenings and the like in the membrane. The installation can be done on top of the concrete slab or on the lowest layer of foam plastic (base insulation) further up on the inside of the plinth elements or in the ground at the excavation bottom. The assembly is done with accessories in a system for joints, perforations, etc. See instructions with details and important measures!

Important!

- Surfaces to be taped and sealed must be clean, dry, and grease-free.

- All joints and pass-throughs must be tight and completely sealed to achieve proper functionality in radon protection.

- As a splicing aid, use only the accessories recommended in the system.

- Consider installation on sunny warm days with cold nights (spring and autumn). Large temperature variations can cause the radon membrane to expand and contract noticeably. Installing the membrane in deliberately shorter lengths results in less expansion and contraction (waves, creases…).

- The assembly should be carried out at temperatures that favor the application of joint aids such as tape, butyl compound, and sleeve. In cooler weather (<+10°C), preheat all components before assembly. Gently heat with a hot air gun during application if necessary. At temperatures ≤ +5°C, supplement the sealing of the joint with T-Fix Adhesive and sealing compound.

- The membrane should be inspected for damage before installation and covering. Any damage should be repaired and sealed with joint aids and/or a possible patch of the membrane.

- The use on moisture-prone surfaces (such as concrete) should be dimensioned according to its moisture content. The membrane exhibits waterproofing properties equivalent to a so-called moisture barrier (see reported vapour transmission resistance) and should be used accordingly.

- When burying, ensure that any fill material above the membrane is radon-free!

- If uncertain about radon measures or moisture problems in the foundation, contact an expert for consultation.

- The products should be stored protected from sunlight and precipitation, and at normal storage temperature.

- After installation, all components of the system should be incorporated into the structure as soon as possible to protect against sunlight (UV) and precipitation.

Articles

- Name Art.nr Specification

Technical specification

- Material: LDPE

- Aging resistance: at least 50 years

- Tensile strength: > 400 N/50 mm (EN 12311-2)

- Elongation at break: > 600% (EN 12311-2)

- Tear Resistance: > 250 N (EN 12310-1)

- Static load: 20 kg (EN 12730:2001 B)

- Resistance to impact: 300 mm (EN 12691 A)

-

Radon transmission:

1.7x10-8m/s

-

Radon permeability:

7.8x10-12 m/s

- Vapor transmission resistance: 7x10⁶ s/m (EN 1931), Sd= ca 185 m

Accessories for Radon Membrane Super

Related Products

Do you need help or have questions about our products?

Try our chatbot

Our chatbot Tea is based on AI and has been trained on all the information available on the website. You can find Tea at the bottom right corner.

Search among questions and answers

We often receive many interesting questions, and we have compiled the most common ones in one place.

Contact our staff

If you need to talk to us, we are of course also available by phone or email!