Product Guide for Roof Underlay

Roofing underlay is a jungle, and the choices you face when selecting one of the many methods for your outer roof are numerous. Therefore, we have compiled an easy-to-use guide for choosing roofing underlay, where you can see which options are suitable for different surfaces and constructions. You can also download the guide as a PDF here.

Roofing underlay

Mounted on a fixed nailable wooden base

| Dimension | Covering area/roll | Waterproofing layer, welded | Surface felt, DIY | Roof shingles | <th>Flat sheet metal (Not profiled sheet!), Slate</th> | <th>Roof Tiles, Profiled Sheet with Seam</th> | Roof Tiles, Curved, Unseamed | Roof Tiles, Flat, Level | Minimum Roof Pitch | <th>Minimum slope with battens without outer covering</th> | Maximum UV exposure time | Product warranty | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T-Roof YAM 2000 |  |

1x10 m | 9.2 m² | AH24 |

AH24 |

No | No | No | No | 1,5° | No | 2 months | 20 years | |||

| T-Roof YAP 2200 |  |

1x10 m | 9.2 m² | No | AH24 |

AH24 |

No | 1,5° | 14° | 3 months | 20 years | |||||

| T-Roof YEP 2500 |  |

1x10 m | 9.2 m² | AH24* |

AH24 |

AH24 |

AH24 |

(!) | 1,5° | 14° | 4 months | 20 years |

Underlayment

Mounted on a fixed nailable wooden base| Dimension | Covering area/roll | Waterproofing layer, welded | Surface felt, DIY | Roof shingles | <th>Flat sheet metal (Not profiled sheet!), Slate</th> | <th>Roof Tiles, Profiled Sheet with Seam</th> | Roof Tiles, Curved, Unseamed | Roof Tiles, Flat, Level | Minimum Roof Pitch | <th>Minimum slope with battens without outer covering</th> | Maximum UV exposure time | Product warranty | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T-Roof YEM 1000 |  |

1x20 m | 18 m² | AH24 |

AH24 |

No | No | No | No | 1,5° | No | 3 months | 20 years | |||

| T-Roof Unum |  |

1x25 m | 22.5 m² | No | No | AH24 |

No | No | 6° | 14° | 2 months | 20 years | ||||

| T-Roof Domo |  |

1x25 m | 22.5 m² | No | No | AH24 |

AH24 |

No | 6° | 14° | 3 months | 20 years | ||||

| T-Roof Evo |  |

1x25 m | 22.5 m² | No | No | AH24 |

AH24 |

No | 6° | 14° | 3 months | 30 years | ||||

| T-Roof Epic |  |

1x12 m | 10.8 m² | No | AH24 |

AH24 |

AH24 |

(!) | 3° | 14° | 12 months | 30 years |

Underlay Roof

| Hanging, diffusion-tight |

Dimension | Covering area/roll | Waterproofing layer, welded | Surface felt, DIY | Roof shingles | <th>Flat sheet metal (Not profiled sheet!), Slate</th> | <th>Roof Tiles, Profiled Sheet with Seam</th> | Roof Tiles, Curved, Unseamed | Roof Tiles, Flat, Level | Minimum Roof Pitch | <th>Minimum slope with battens without outer covering</th> | Maximum UV exposure time | Product warranty | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X-Foil Roof/Duo |  |

Multiple items | Multiple items | No | No | No | No | AH24 |

AH24 |

No | 14° | 14° | 2 months | 30 years | ||

| T-Diff Pro |  |

1.5x30 m | At least 39 m² | No | No | No | No | AH24 |

AH24 |

No | 14° | 14° | 4 months | 30 years |

-

Acceptable -

(!)

Acceptable if the boiler supplier's

instructions approve! -

Recommended -

Optimal -

AH24

According to Ama-Hus 2024 requirements -

No

Not intended for this! -

DIY

Do it yourself -

*

As coats/strips

Accessories

Primer K-80

UNDERCOAT

Sealant K-36

GLUING AND SEALING

T-Fix

GLUING, SEALING, JOINTING

T-Roof Multi Strip

STRIP FOR BASE PLATE, VALLEY GUTTER, RIDGE AND JOINT

Roofseal-T / Corner

SEALING

Intended

use:

Primer, adhesion enhancer for surfaces such as concrete, brick, and roofing underlay. Use if necessary before applying Sealant Adhesive.

For gluing and sealing of roofing underlay and

underlay fabric. Sealing and repair of joints and pass-throughs on the outer roof and penetrations on the outer roof.

For bonding and sealing of roofing underlay and underlay fabric. Sealing and repair of joints and pass-throughs on the roof.

Condensation and moisture protection for all roofs under the base plate, in the valley, ridge, and joint strip between roof cassettes.

Repair tape for minor damages

and sealing tape as well as corner sealing sheets at detail connections (e.g., corners, etc.) on roofing underlay / underlay fabric.

Features:

Thin liquid black bitumen emulsion. Drying time approximately 2-3 hours (+20°C).

Black elastic bitumen paste. Dust dry in about 5 hours (+20°C). Drying time approximately 1-14 days depending on temperature.

Plastic and permanently elastic black sealant made of hybrid polymer.

Fully adhered self-adhesive black

underlayment of bitumen.

Stretchable single-sided tape

with butyl adhesive and UV-protected

aluminum foil.

Application:

With a semi-soft brush or roller.

Caulking gun or putty. Priming

if needed with primer K-80.

With a caulking gun. Pre-coating

if needed with primer.

With a firm handshake.

With firm hand pressure or roller.

On roofing underlay (sanded)

pre-treatment with Primer K-80.

Consumption:

0.5-0.6 liters/m2 coating.

Cross joint: 0.1 liters/joint. Valley: 0.2 liters/meter. Chimney base:

0.3 liters/chimney.

Cross joint: 0.1 liters/joint. Valley: 0.2 liters/meter. Chimney base: 0.5-1 liter/chimney. When sealing: As needed.

1 m per 1 m base plate, valley, ridge or joint.

For minor damages: Damage size +40 mm all around. For corners: 1 sheet per corner. 1 m per 1 m joint.

T-Butyl

SEALING AND JOINT

T-Flex Outdoor

SEALING

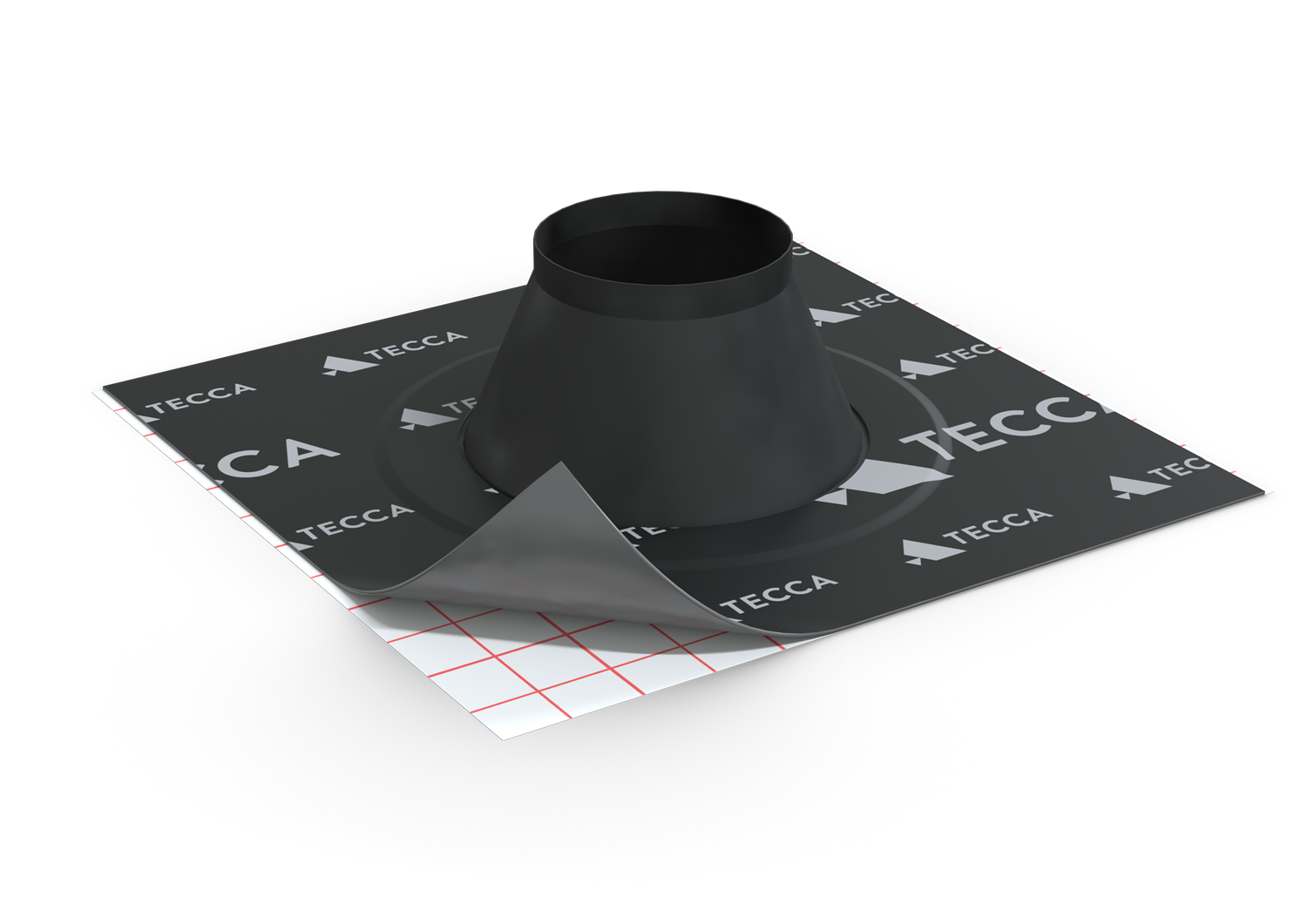

T-Sleeve Butyl

SEALING

Sealing Tape

SEALING

Distance

DISTANCE

Intended use:

Joint and sealing tape for suspended underlay roofs like X-Foil and T-Diff.

Repair tape for minor damages

(<100 mm) on suspended sub-ceiling like X-Foil and T-Diff.

For sealing round pass-throughs in roofing underlay, underlay fabric

or suspended underlay roof.

Sealing tape for hanging

underlay roof between nail battens

(counter battens) and the membrane.

For securing suspended sub-ceilings that ensure

a drape of the fabric between the rafters.

Features:

Double-sided tape in gray

permanent elastic butyl mass.

Diffusion-tight, single-sided adhesive, and UV-protected aging-resistant black tape.

UV-protected aluminum foil with

butyl adhesive and sheath of elastic EPDM rubber.

Soft single-sided green foam tape.

Rigid foam profile.

Application:

The splice tape is attached to one of

the base with the protective strip on

opposite side intact. Assembly

should be done with full pressure on the seam.

With firm hand pressure or roller.

With firm hand pressure or roller. On

roofing underlay (sanded) pre-treatment with Primer K-80.

With a firm handshake.

By hand.

Consumption:

1 m per 1 m joint.

Damage size + 40 mm all around.

1 mare per pass-through.

1 m per 1 m battens.

2 pcs per m² roof.

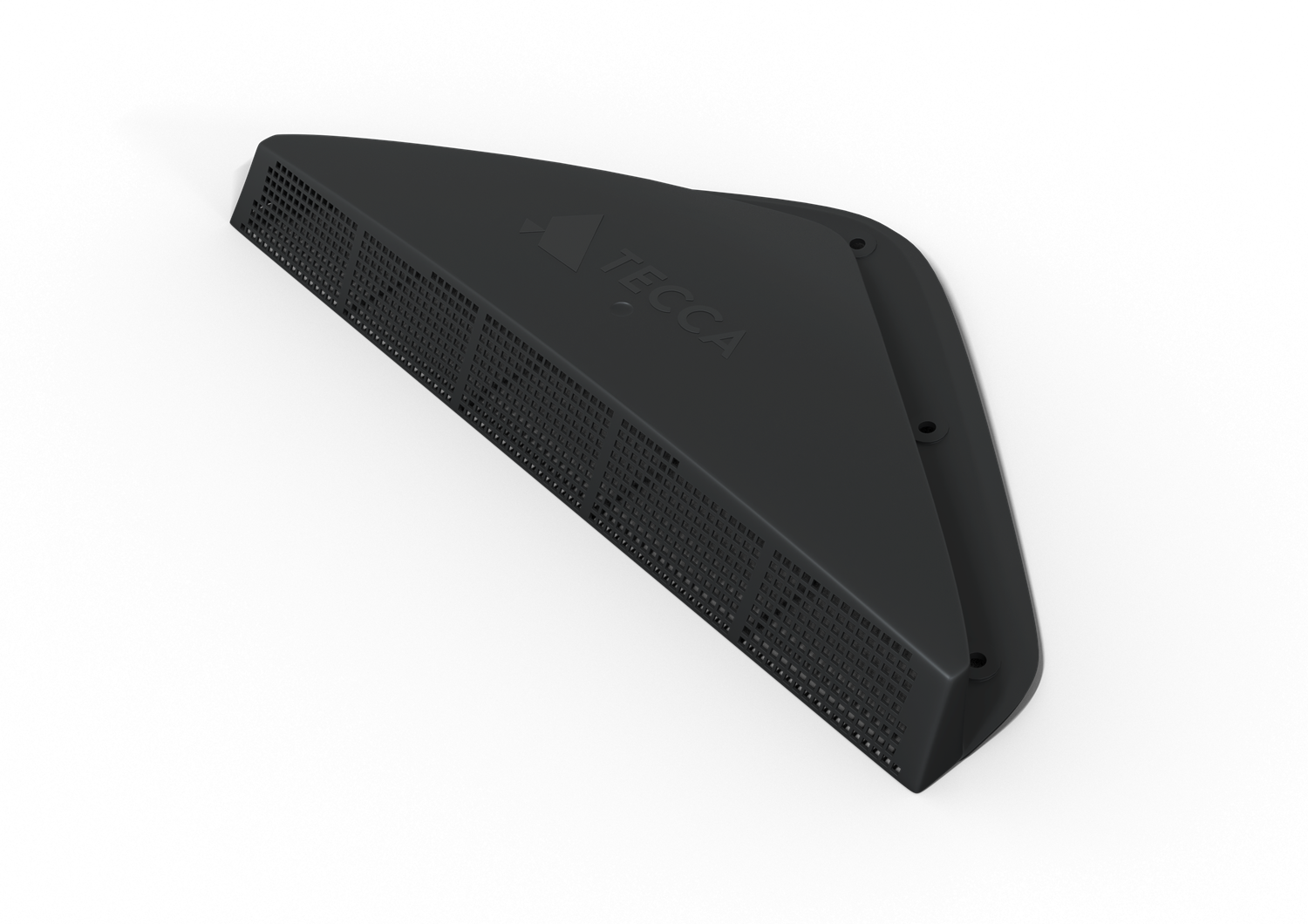

Intended use:

To ventilate an air gap or

cold attic (can replace tight ridge and/or eaves) when the outer covering

has roofing underlay or underlay fabric on solid wood substrate with battens over.

Features:

Homogeneous UV-protected black

polypropylene (PP).

Application:

With 5 mounting screws per valve.

Consumption:

If needed, 1-2 pieces per truss bay at

ridge or alternatively eaves.